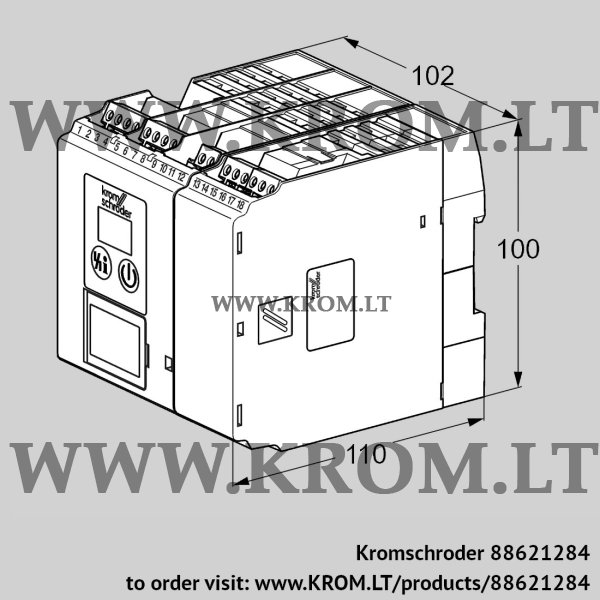

Kromschroder FCU 500QC1F1H1K1-E, protective system control (88621284)

Brand: Kromschroder

SKU:

88621284

Kromschroder

88621284

Kromschroder protective system control

Housing for control cabinet installation, for monitoring and controlling central safety functions in multiple burner systems on industrial furnaces, long service life due to replaceable power module for fail-safe outputs. Display of the program status, unit parameters and flame signal. Manual operating mode. Diagnosis and adjustment of unit parameters via optical interface using PC software BCSoft. EC-type tested and certified, CSA and FM approved, certified for systems up to SIL 3 (compliant with PL e).

Series 500

Mains voltage: 120 V AC, 50/60 Hz

With integrated tightness control or POC

Modulating capacity control with interface for actuator IC

With temperature monitoring

Screw connection terminals

EU certified, CSA and FM approved, certified for systems up to SIL 3 (compliant with PL e)

Individual packaging

10 Emergency stop with safety shut-down

12 High gas pressure protection with fault lock-out

13 Low pressure cut-off with fault lock-out

15 Air deficiency cut-out with fault lock-out

19 Safety time during operation: 1 s

20 Maximum temperature monitoring using safety temperature limiter (STL)

22 Type K double thermocouple NiCr-Ni

23 Temperature difference limit value: 50°C

24 Lower limit for high temperature operation: 750°C

25 Upper limit of the furnace or flue gas temperature: 350°C

26 Temperature hysteresis: 50°C

27 Pre-purge during high temperature operation

29 Fan switched on in the event of fault

30 Fan run-up time tGV: 0 s

32 Air flow monitoring during controlled air flow off, valve opens

34 Pre-purge time tPV: 300 s

35 Air flow monitoring during pre-purge with safety shut-down

37 Post-purge time tPN: 0 s

38 Post-purge: actuator (if there is one) moves to the OPEN position and the air flow is not monitored.

44 Controller enable signal delay time tRF: 0 s

45 Minimum enable time: 0 s

46 After operating signal: no controller enable

47 Controller enable (timeout): 60 min.

51 Valve proving system: permanent tightness test via proof of closure function (POC)

53 Tightness control test volume: Vp

54 Tightness control: pressure reduction Vp2 in standyby

55 Relief valve V3 opening time (tL3): 0 s

56 Measurement time Vp: 10 s

57 Measurement time Vp1 + Vp2: 10 s

58 Measurement time Vp1 + Vp2 + Vp3: 3600 s

59 Valve opening time V1 (tL1): 2 s

60 Valve opening time V2 (tL2): 2 s

62 Minimum pause time tfP: 0 s

63 Switch-on delay time tE: 0 s

65 Filling time before start-up: 0 s

67 Operating time in Manual mode limited to 5 min.

72 Function of terminal 67: fault lock-out if no signal from automatic burner control unit

77 User-defined password

Housing for control cabinet installation, for monitoring and controlling central safety functions in multiple burner systems on industrial furnaces, long service life due to replaceable power module for fail-safe outputs. Display of the program status, unit parameters and flame signal. Manual operating mode. Diagnosis and adjustment of unit parameters via optical interface using PC software BCSoft. EC-type tested and certified, CSA and FM approved, certified for systems up to SIL 3 (compliant with PL e).

Series 500

Mains voltage: 120 V AC, 50/60 Hz

With integrated tightness control or POC

Modulating capacity control with interface for actuator IC

With temperature monitoring

Screw connection terminals

EU certified, CSA and FM approved, certified for systems up to SIL 3 (compliant with PL e)

Individual packaging

10 Emergency stop with safety shut-down

12 High gas pressure protection with fault lock-out

13 Low pressure cut-off with fault lock-out

15 Air deficiency cut-out with fault lock-out

19 Safety time during operation: 1 s

20 Maximum temperature monitoring using safety temperature limiter (STL)

22 Type K double thermocouple NiCr-Ni

23 Temperature difference limit value: 50°C

24 Lower limit for high temperature operation: 750°C

25 Upper limit of the furnace or flue gas temperature: 350°C

26 Temperature hysteresis: 50°C

27 Pre-purge during high temperature operation

29 Fan switched on in the event of fault

30 Fan run-up time tGV: 0 s

32 Air flow monitoring during controlled air flow off, valve opens

34 Pre-purge time tPV: 300 s

35 Air flow monitoring during pre-purge with safety shut-down

37 Post-purge time tPN: 0 s

38 Post-purge: actuator (if there is one) moves to the OPEN position and the air flow is not monitored.

44 Controller enable signal delay time tRF: 0 s

45 Minimum enable time: 0 s

46 After operating signal: no controller enable

47 Controller enable (timeout): 60 min.

51 Valve proving system: permanent tightness test via proof of closure function (POC)

53 Tightness control test volume: Vp

54 Tightness control: pressure reduction Vp2 in standyby

55 Relief valve V3 opening time (tL3): 0 s

56 Measurement time Vp: 10 s

57 Measurement time Vp1 + Vp2: 10 s

58 Measurement time Vp1 + Vp2 + Vp3: 3600 s

59 Valve opening time V1 (tL1): 2 s

60 Valve opening time V2 (tL2): 2 s

62 Minimum pause time tfP: 0 s

63 Switch-on delay time tE: 0 s

65 Filling time before start-up: 0 s

67 Operating time in Manual mode limited to 5 min.

72 Function of terminal 67: fault lock-out if no signal from automatic burner control unit

77 User-defined password

Replacing a Kromschroder FCU 500QC1F1H1K1-E, 88621284 protective system control is a good solution to make your equipment work again. We offer a wide range of Kromschroder spare parts for burners, gas trains etc. We supply original Elster (Kromschröder) & Honeywell (Maxon) products.

If you have any queries about Kromschroder control units or any other Kromschroder spare parts, please write us at 624burner@gmail.com, quoting the item code 88621284.

- Voltage 120 V AC

- Weight, kg 0,78

- Commodity code 90268020

- Country of origin DE